Researchers turn disposable cups into vitamin C health trackers

Key takeaways

- UC San Diego scientists have developed a battery-free sticker that turns disposable cups into vitamin C monitors using fingertip sweat.

- The flexible, low-cost sensor uses a biofuel cell for power and sends real-time data wirelessly, enabling effortless “unawareable” health tracking.

- Researchers say the technology is scalable for integration into everyday F&B packaging like coffee cups, cans, and bottles.

Scientists at the University of California San Diego (UC San Diego) in the US have created an battery-free electronic sticker for drinking cups capable of detecting a person’s vitamin C levels using the sweat on their fingertips.

The flexible sticker can be attached to the outside of a cup to collect information while the user consumes the drink and sends the results wirelessly to a nearby laptop.

“The Center for Wearable Sensors has spent the last decade developing electrochemical biosensors that can monitor physiochemical parameters on humans, leading to exciting new insights in health. These sensors, however, are inherently disposable and don’t last forever,” study author Patrick Mercier, a professor in the Department of Electrical and Computer Engineering at the UC San Diego Jacobs School of Engineering, tells Packaging Insights.

Mercier says that by turning everyday objects like cups or bottles into smart sensors, people can gain real-time insights into their health and wellness without changing their daily routine.

“We’re moving toward a future of ‘unawareables’ — devices that are unobtrusive and essentially invisible so that you are unaware that you’re even using them. You just go about your day and your drinking cup can give you access to all this rich information.”

Health screening to-go

The research team points out that micronutrient deficiencies, including in vitamin C, affect millions of people worldwide. Meanwhile, in the US, a conventional vitamin C laboratory test costs around US$50, making regular monitoring impractical.

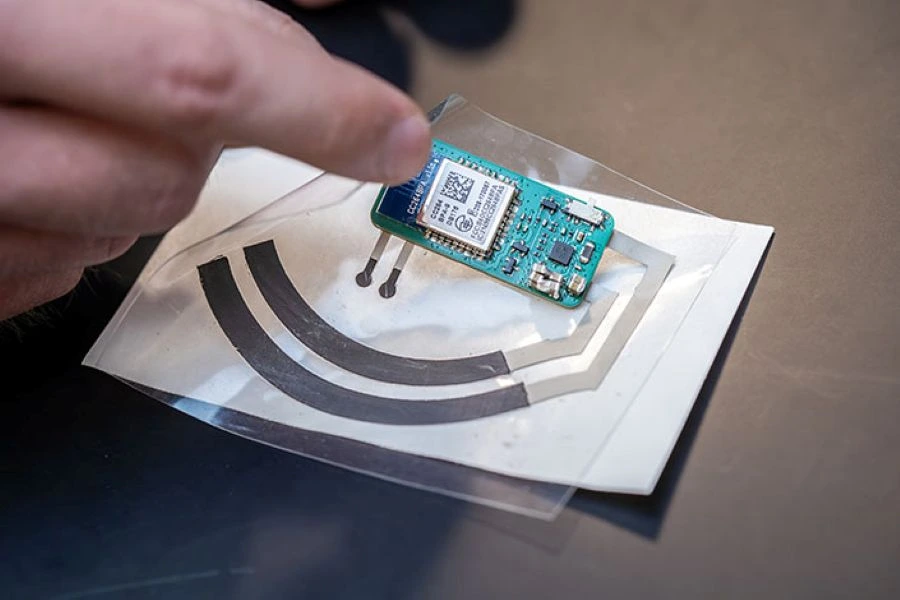

The solution features a sticker consisting of a biofuel cell beneath a porous hydrogel pad that collects fingertip sweat, a printed circuit board, and a vitamin C sensor. It is built on a flexible, adhesive polymer sheet.

Patrick Mercier, professor at the UC San Diego Jacobs School of Engineering.The circuit board interprets the signals from the vitamin C sensors and transmits the information to a nearby device through bluetooth.

Patrick Mercier, professor at the UC San Diego Jacobs School of Engineering.The circuit board interprets the signals from the vitamin C sensors and transmits the information to a nearby device through bluetooth.

The built in biofuel cell converts chemicals found in human sweat into electricity which powers the custom-built circuit coats and the vitamin C sensor, allowing integration in on-the-go, single-use packaging.

“We were looking for opportunities to integrate such sensors into objects we could use on a daily basis that are also inherently disposable,” explains Mercier.

“Cups seemed like a good idea — we can put the sticker on the cup (or in the future, the sensor will just be part of the disposable cup directly), use it, then throw it away when we are done.”

He highlights that by using a biofuel cell instead of a battery to power the device, and leveraging sweat that is naturally present in the fingertip as a source of biofuel and as a way to do measurements, the researchers keep the cost and environmental impact of such a device minimal.

“This allows users to get powerful insights into their bodies without having to change their behavior in any way.”

Packaging integration at scale

Mercier tells us he “certainly” thinks the sticker solution can be scaled and integrated into F&B packaging. “Disposable coffee cups, soda cans, water bottles, and more, would all be appropriate.”

The sticker consists of a biofuel cell (black arches), pad collecting sweat, circuit, and vitamin C sensor (small black circles).“Fortunately, the underlying technology is quite low cost and easy to scale: a screen printed biosensor and a small microchip will make the cost only a few US cents at scale,” he adds.

The sticker consists of a biofuel cell (black arches), pad collecting sweat, circuit, and vitamin C sensor (small black circles).“Fortunately, the underlying technology is quite low cost and easy to scale: a screen printed biosensor and a small microchip will make the cost only a few US cents at scale,” he adds.

The device is also low cost because it does not need a battery due to its biofuel charging solution.

The research team argues that the affordability of the device could make future versions disposable and widely accessible, particularly in low-resource areas.

“We have what we call a university-grade prototype right now. To scale up we’d need to partner with a company to commercialize.”