Milk-based biodegradables can replace plastic in food packs, find scientists

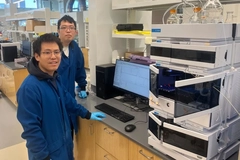

Professor Youhong Tang, from the Advanced Materials Laboratory at Flinders University, with chemical engineering researcher Nikolay Estiven Gomez Mesa.

Professor Youhong Tang, from the Advanced Materials Laboratory at Flinders University, with chemical engineering researcher Nikolay Estiven Gomez Mesa.Researchers have synthesized a biodegradable film for food packaging by combining calcium caseinate — a commercially available derivative of casein, the main protein in milk — with modified starch and bentonite nanoclay.

The study, published in Polymers, details the development of functional and biodegradable films using biopolymer blends and nanoclay suspensions. To enhance the film’s flexibility and durability, glycerol and polyvinyl alcohol were added.

The project was conducted in a collaboration between Flinders University, Australia, and researchers from Universidad de Bogotá Jorge Tadeo Lozano, Colombia. The team explores innovative polymers as part of the Nanobioengineering Research Group.

Chemical engineering researcher Nikolay Estiven Gomez Mesa, tells Packaging Insights: “These films offer a range of advantages over traditional plastic materials, starting with sustainability. They’re made from renewable sources like starch and clay, and are fully biodegradable, helping to combat long-term plastic pollution.”

“We were experimenting with caseinates to make milk-based nanofibers and found that they could be used to cast polymers similar to common packaging materials.”

Improved functionality

Through the inclusion of nanoclay, the films deliver “superior barrier performance by reducing water vapor permeability and shielding against UV light, which helps extend the shelf life of packaged goods,” according to Gomez.

The incorporation of bentonite improved the film’s mechanical properties, outperforming similar films without polyvinyl alcohol.“Mechanically, the combination of these biomaterials yields a polymer that strikes a balance between strength and flexibility, and minimizes brittleness.”

The incorporation of bentonite improved the film’s mechanical properties, outperforming similar films without polyvinyl alcohol.“Mechanically, the combination of these biomaterials yields a polymer that strikes a balance between strength and flexibility, and minimizes brittleness.”

“Recovering caseinates, including sodium caseinate sourced from expired pasteurized skim milk, can lead to valorizing dairy waste streams, turning discarded byproducts into biodegradable films that support circular economy initiatives.”

The scientist highlights that the entire formulation was designed to use inexpensive ingredients that are biodegradable to create an affordable alternative for traditional materials with enhanced characteristics.

Performance and safety tests

The study’s biodegradability testing revealed a consistent degradation trend, with complete disintegration projected within 13 weeks under normal soil conditions. A microbial analysis also showed that the quantity of bacterial colonies remained within permissible levels for non-antimicrobial biodegradable films.

“Casein–starch-based films are naturally hydrophilic, which can limit their effectiveness in packaging foods with high moisture content. However, the incorporation of nanoclay helps address this by creating tortuous pathways that slow water vapor transmission, enhancing both durability and barrier performance,” explains Gomez.

“For oily foods, additional coatings, such as the proposed nanostructure, could be explored to improve resistance, depending on industry requirements.”

The researchers recommend further antibacterial evaluations in further testing and development, and emphasize that to ensure safety, all food-contact packaging must undergo migration and stability testing before commercial use.

“Although our study demonstrates promising functionality, further antibacterial evaluation is essential before scaling up, particularly against foodborne pathogens like E. coli, Listeria, and Salmonella, which are especially relevant for dairy applications such as cheese packaging. These steps are critical to meeting international standards for safety and performance,” Gomez concludes.